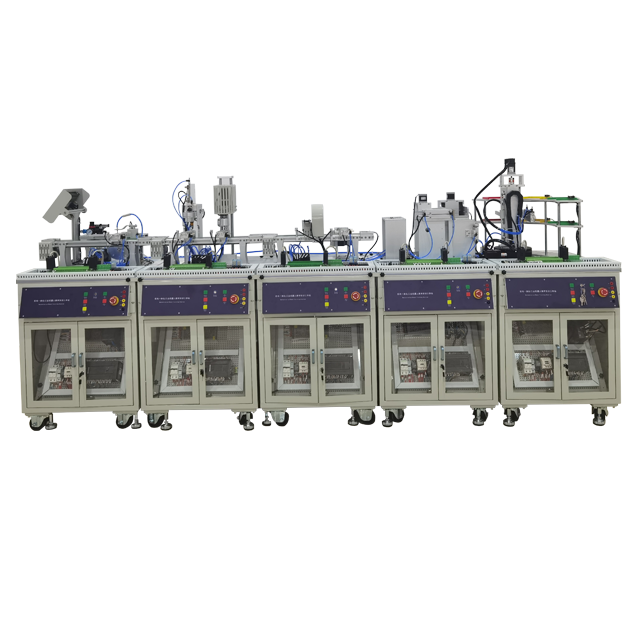

一、Product Overview

This equipment is developed in accordance with the training skills requirements of national vocational standards issued by the Ministry of Human Resources and Social Security, such as "Maintenance Electrician" Senior (Level 3), "Technician (Level 2)," Machine Repair Fitter "Senior (Level 3)," Assembly Fitter "Senior (Level 3)," Programmable Control System Designer "Senior (Level 3), and" Technician (Level 2). The equipment adopts a modular structure combination application design concept, integrating machinery, electricity, and gas, fully reflecting the teaching and training of professional skills such as mechanical assembly and adjustment, electrical wiring, software programming, debugging and maintenance. Suitable for teaching, practical training appraisal, and skill competitions of professional courses such as maintenance electricians, mechatronics integration, industrial automation, and programmable control system designers in various technical and vocational colleges.

二、Technical parameters

1) Working power supply: three-phase five wire 380V ± 5% 50HZ;

2) Safety protection: leakage protection, overcurrent protection, fuse protection;

3) Boundary dimension: 3100 mm × 1100 mm × 1200 mm ;

4)P L C:FX3u-48MR FX3u-48MT FX3u-485BD FX3u-1PG FX3u-3A;

5) Frequency converter: FR-E720-0.75K;

6) Stepper motor: two-phase four beat 42BYG;

7) Servo system: MR-E-10A;

8) Touch screen: TPC7062GI;

9) Sensor: OMRON brand;

10) Pneumatic components: SMC AirTAC brand;

11) Rated power: 2KW;

12) Environmental temperature: -10 ℃~50 ℃;

13) Relative temperature: ≤ 85%.

三、Practical training projects

1. PLC detects multiple material properties

2. PLC's absolute positioning control of conveyor belt operation

3. Pulse positioning control of PLC on transmission belt

4. PLC's mixed positioning control for conveyor belts

5. Basic motion control of the dual axis stacker by PLC

6. Use pulse commands to control stepper motors

7. PLC automatic control of multi-axis industrial robots

8. PLC control assembly unit

9. PLC for single and dual axis control of stacker crane

10. PLC automatic control of warehouse outbound and inbound operations

11. PLC control of warehouse space allocation

12. Touch screen monitoring and management of the overall training process

13. Set the entire system parameters through the touch screen

14. Touch screen query and processing of system alarm codes

15. Practical training on multi-level permission settings for touch screens

16. Touch screen fault setting, diagnosis and troubleshooting