一、Product Overview

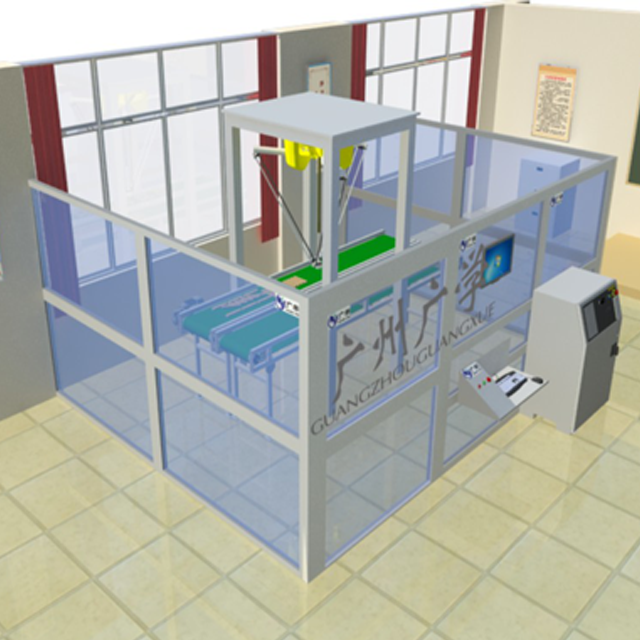

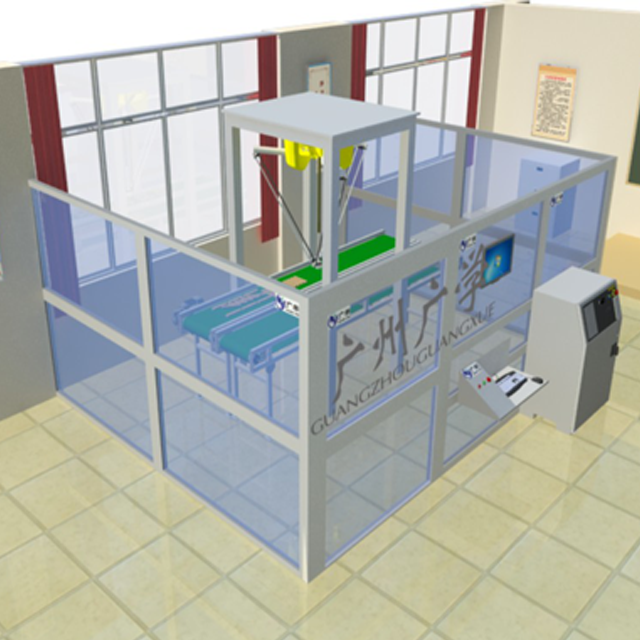

The GX-R15 industrial robot detection and sorting workstation is based on the actual application in the factory, and optimized and improved according to the teaching characteristics to achieve both teaching authenticity and safety, while ensuring the durability and high cost-effectiveness of the equipment. Instructional design has been carried out for the most common handling methods of industrial robots. The handling methods of industrial robots in production line processes are common and difficult to work. The main components of this workstation are simulated production lines, industrial robots, pallets, and visual systems.

二、Technical parameters

1) Six axis robot standard configuration: ABB IRB1410 6-degree of freedom specialized welding industrial robot (optional with Mitsubishi, KUKA, Hirosus, etc.);

2) Boundary dimension: L3000mm × W3000mm × H1800mm;

3) Frequency converter: FR series;

4) Working power supply: three-phase four wire 380V ± 5% 50HZ;

5) Safety protection: leakage protection, overcurrent protection, short circuit protection;

6) Environmental temperature: -10~50 ℃;

7) Relative temperature: ≤ 85%;

8) Overall weight: 180kg.

三、Practical training projects

1. Use robot offline software for real-time program, IO, and robot 3D dynamic motion monitoring;

2. Practical training on robot programming, assembly and maintenance, automatic welding process, etc. based on ABB robots;

3. Based on the basic principles, structure, and engineering application cases of ABB robots;

4. Application Cases of Special Software for Stacking Robot

5. Classification and stacking of industrial robots;

6. Visual system applications.