一、Product Overview

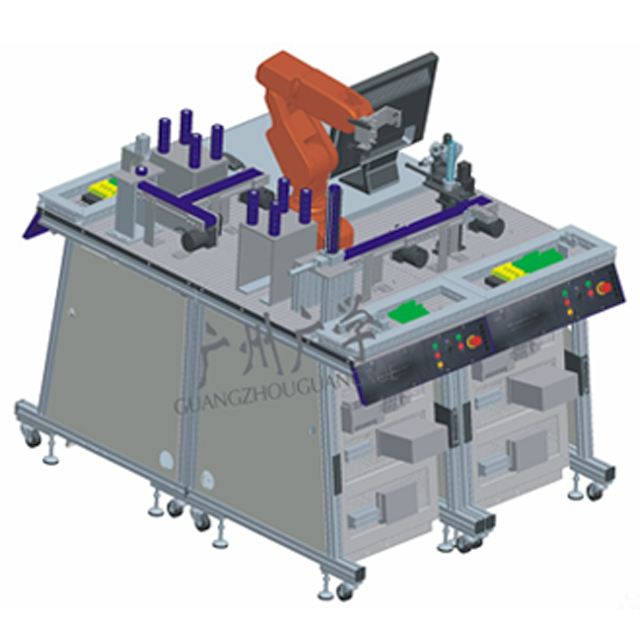

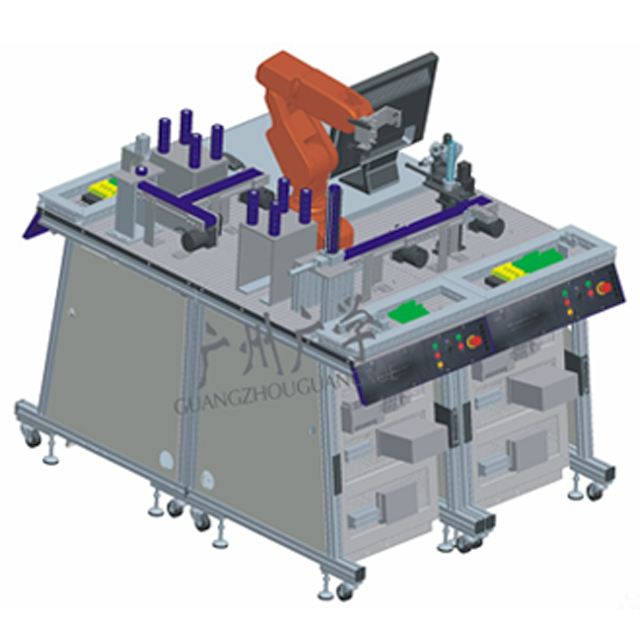

The GX-R12 industrial robot palletizing workstation is a typical industrial robot skill training application teaching equipment. The palletizing robot is the core equipment of a flexible automation system, consisting of a multi joint 6-degree of freedom robot, controller, and training platform system. Simulate the stacking of car tires, glass windows, and goods. It is possible to expand the configuration of visual systems and 3D printing technologies to achieve more comprehensive teaching and training tasks. The development of task models integrates fun and entertainment, which can increase students' interest in learning.

二、Technical parameters

1) Standard configuration for six axis robots: ABB 6 degree of freedom industrial robots (optional with Mitsubishi, KUKA, Hirosus, Xinshida, etc.);

2) The application links equipped with industrial robots include the feeding process of conveyor belts, the robot stacking process, and the warehousing process;

3) Boundary dimension: L3000mm × W3000mm × H1500mm;

4) Working power supply: single-phase three wire 220V ± 5% 50HZ;

5) Safety protection: leakage protection, overcurrent protection, short circuit protection;

6) Environmental temperature: -10~50 ℃;

7) Relative temperature: ≤ 85%;

8) Overall weight: 180kg.

三、Practical training projects

1. Basic understanding of industrial robots;

2. Installation and wiring of industrial robot body and controller;

3. Initialization and parameter recovery of industrial robots;

4. Industrial robot teaching device motion operation;

5. Point-to-point teaching of industrial robots;

6. Basic parameter settings for industrial robots;

7. Basic motion instruction learning for industrial robots;

8. Programming of industrial robots based on teaching aids;

9. Industrial robot control applications;

10. Basic wiring methods for industrial robots;

11. Design case of automatic palletizing programming based on industrial robots.