- HOME

- ABOUT US

-

Product Center

- Industrial robot series

- Electromechanical integration series

- Electrical series

- Electronic Series

- Multimedia teaching control system

- Intelligent Building Series

- CNC maintenance series

- Refrigeration and heating series

- Household appliance maintenance assessment equipment series

- Mechanical Engineering Series

- Mobile training vehicle

- Elevator series

- Automotive Maintenance Series

- New energy series

- Automation series

- News Center

- Case Center

- Data Download

- Contact Us

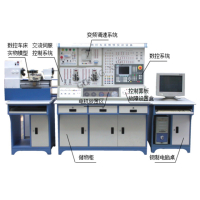

GX-SK21A CNC Lathe Maintenance Training Equipment

一、Product Overview

This set of equipment is jointly developed by Guangzhou Guangxue Teaching Equipment Co., Ltd., the Vocational Skills Appraisal Center of the Ministry of Labor and Social Security, the China High Skills Equipment Research Institute, the Guangdong Department of Labor's Electrical Expert Group, and other experts, professors, and engineers for the maintenance of CNC machine tools and the vocational training and skill appraisal of electrical technicians and senior technicians. It is a standardized training equipment for new technologies and processes that integrates PLC, frequency converter, and AC servo. Suitable for advanced vocational colleges, technician colleges, technical schools, and secondary vocational colleges to cultivate students' practical skills in programming methods, electrical design, installation, debugging, and maintenance of CNC machine tools. It is also suitable for the training, teaching, experimental operation, assessment, appraisal, and other uses of electrician and high skilled talents.

This set of equipment adopts a modular design, mainly composed of a power module, an operation panel module, a variable frequency speed control module, an AC servo module, a motor module, a button module, and a fault setting module. This equipment adopts an open design, and students can conduct practical training on single skills such as CNC programming, AC servo operation, frequency converter operation, etc. on the equipment. They can also simulate the control requirements of the system in industrial production sites according to their respective situations, and carry out self-designed, combined installation, and debugging to better cultivate students' hands-on and analytical abilities. At the same time, this equipment also provides a necessary platform for researchers to further understand the structure of CNC lathes and carry out secondary development of CNC systems.

二、Technical Parameter

1)Working power supply: three-phase five wire 380V ± 5% 50Hz;

2)Safety protection: leakage protection (operating current ≤ 30mA), overcurrent protection, fuse protection;

3)Rated power: ≤ 0.75Kw;

4)Environmental temperature: -10 ℃~40 ℃;

5)Relative humidity: ≤ 90% (25 ℃);

6)CNC system: GSK-980TD1;

7)Frequency converter: FR-E540-0.75KW;

8)AC servo: TD98B;

9)Feed motor: 300W, including pulse encoder;

10)Spindle motor: 180W;

11)Boundary dimension: 2650 ×800× 1650mm;

12)Model size: 600 × 700× 580mm;

13)Equipment weight: 120kg。

三、Practical training projects

1) Data storage and initialization experiment of GSK-980TD1 CNC system in Guangzhou;

2) Operation and interface experiments of CNC system;

3) Servo system control experiment;

4) CNC system control servo motor experiment;

5) Frequency conversion and speed regulation experiment of frequency converter (1);

6) Frequency conversion and speed regulation experiment of frequency converter (2);

7) Installation and fault diagnosis experiment of spindle encoder;

8) Electric tool holder experiment (lathe);

9) Communication experiment of CNC turning and milling machine system;

10) CNC system PLC programming and linking experiment;

11) Conduct PLC programming practice experiments using I/O units;

12) Practice and assessment of maintenance and troubleshooting of CNC system circuits.