- HOME

- ABOUT US

-

Product Center

- Industrial robot series

- Electromechanical integration series

- Electrical series

- Electronic Series

- Multimedia teaching control system

- Intelligent Building Series

- CNC maintenance series

- Refrigeration and heating series

- Household appliance maintenance assessment equipment series

- Mechanical Engineering Series

- Mobile training vehicle

- Elevator series

- Automotive Maintenance Series

- New energy series

- Automation series

- News Center

- Case Center

- Data Download

- Contact Us

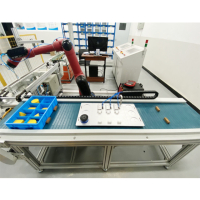

GX-R19 Intelligent Manufacturing Production Line Comprehensive Training System

一、Product Overview

The GX-R19 intelligent manufacturing production line comprehensive training system consists of six parts: industrial robots, AGV robots, tray production lines, workpiece box production lines, visual systems, and three-dimensional warehouses.

The main work objective of the system is to transport the workpieces that have been taken out of the three-dimensional warehouse to the pallet production line through AGV robots, identify the workpieces through the visual system on the pallet production line, and then use industrial robots to grab and classify the workpieces into boxes.

二、Practical training projects

1. Understand the application of sensors

2. Observe the application of pneumatic components

3. Master PLC control technology

4. Workpiece loading program control

5. Workpiece handling program control

6. Workpiece detection program control

7. Workpiece Handling and Installation Program Control

8. Workpiece installation program control

9. Workpiece classification program control

10. Multi workstation program control

11. Work Unit Networking Program Control

12. Stepper motor drive control

13. Installation and debugging of electrical control system

14. Mechanical System Installation and Debugging

15. Motor drive debugging

16. System maintenance and fault detection technology

17. Installation of pneumatic directional control circuit

18. Installation of pneumatic speed control circuit

19. Installation of pneumatic sequential control circuit

20. Installation of Pneumatic Manipulator

21. Connection of pneumatic system air circuit

22. Position adjustment of magnetic switches

23. Pneumatic system debugging

24. Installation of swing control circuit

25. Parameter Setting and Operation of the Inverter Panel

26. Frequency converter panel controls AC motor speed regulation

27. Adjustment of the coaxiality of the transmission device

28. Installation and Adjustment of Belt Conveyor

29. Installation and Debugging of Handling Robot Equipment

30. Installation and debugging of feeding equipment

31. Installation and debugging of automatic production line equipment

32. Programming of Belt Conveying Inspection Program

33. Programming of Pneumatic Manipulator Control Program

34. Automatic production line control program writing

35. Installation and debugging of multiple sensors

36. Automatic control of belt conveyor detection

37. Installation and debugging of PLC control system

38. Installation and Debugging of Automatic Production Line